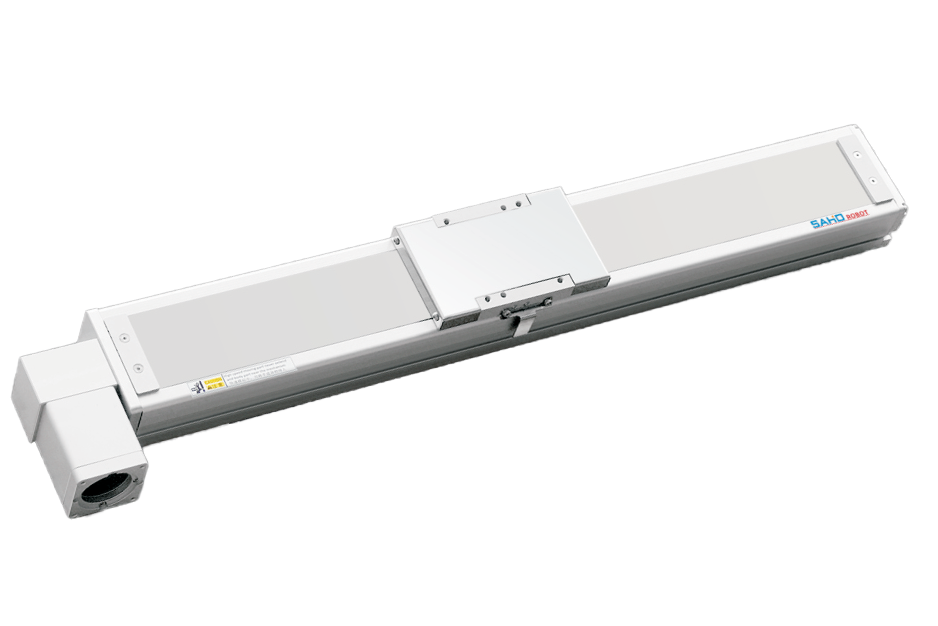

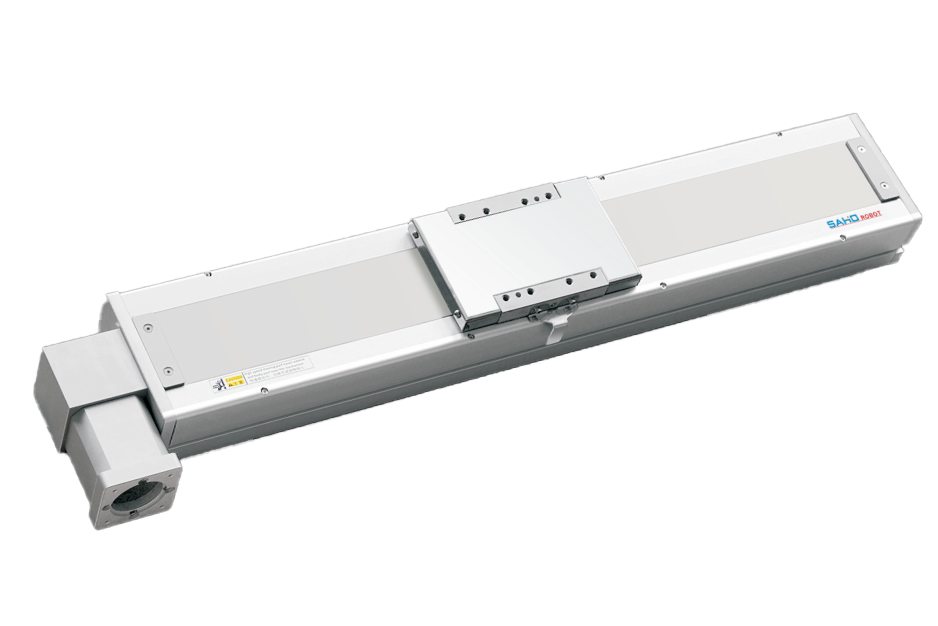

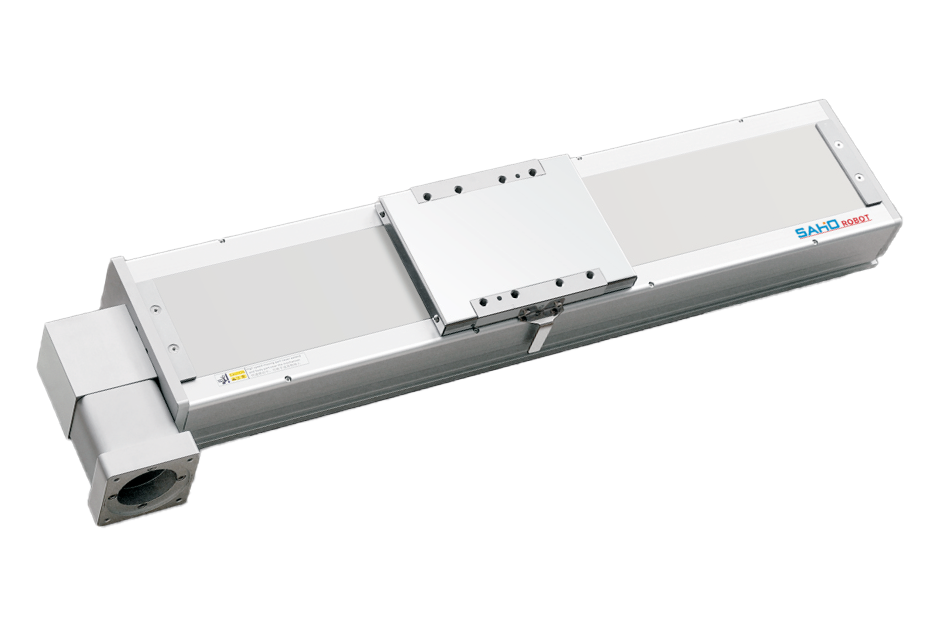

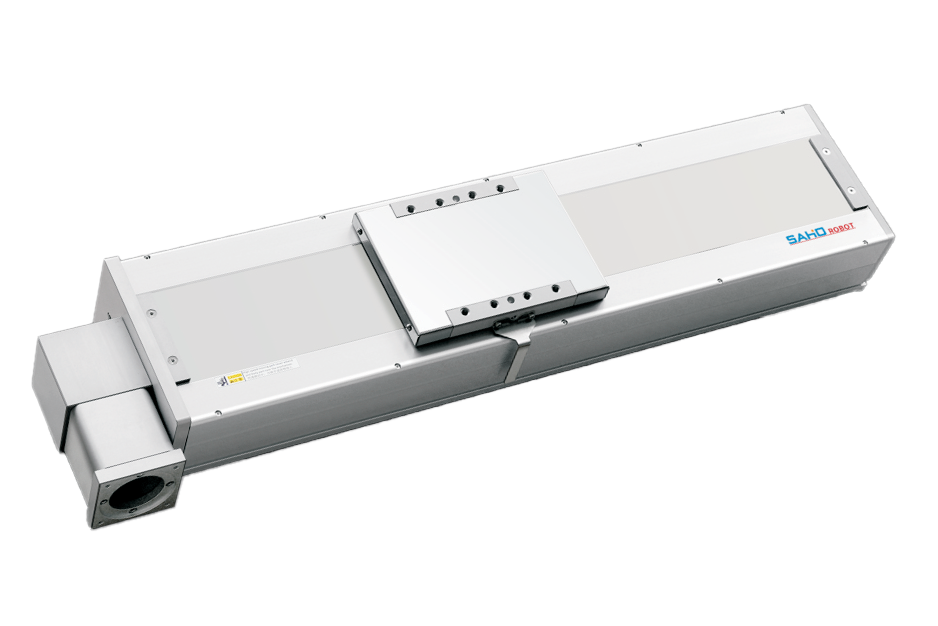

MSTM Series

Frequently Asked Questions

What’s the difference between a ball screw, belt, and rack & pinion...

Ball screw modules offer high precision and rigidity for accurate positioning.

Belt modules are ideal for high-speed, long-travel motion.

Rack & pinion modules handle heavy loads and extra-long strokes.

How do I select the right linear module?

Selection depends on load, travel distance, speed, installation direction, and precision requirements. Our engineers can assist with model selection if you share your application data.

Can the module be mounted vertically?

Yes, but vertical installation requires a brake motor or mechanical lock to prevent gravity drop.

What is the repeat positioning accuracy?

Ball screw type: ±0.01 mm; Belt type: ±0.05 mm; Rack & pinion type: ±0.1 mm.

Do the modules require maintenance?

Yes. Apply grease every 500 operating hours or 3 months and keep the guideways clean.

Which motor brands are compatible?

Compatible with Delta, Mitsubishi, Panasonic,Yaskawa, Inovance, and most standard servo motors.

Can you provide custom stroke or dust-proof options?

Yes. Customized stroke lengths, dust covers, and mounting interfaces are available upon request.

What is the delivery lead time?

Standard models: 7–15 days. Customized models: depends on machining requirements.