Date:2025-09-04 Click:229

Primary consideration factor: with or without iron core?

There are two main types of linear motors: with iron core and without iron core, which refers to whether the winding of the primary part (similar to the stator in a rotating motor) is installed in a laminated iron layer or in epoxy resin. Determining whether an application requires a linear motor with or without an iron core is usually the first step in design and selection. Iron core linear motors are most suitable for applications that require extremely high thrust. This is because the lamination of primary components contains "teeth" (protrusions) that gather magnetic flux to the magnets of secondary components (similar to rotors in rotating motors). The magnetic force between the iron core of the primary part and the permanent magnet of the secondary part enables the motor to provide higher thrust.

Ironless linear motors typically have lower thrust, making them unsuitable for applications with extremely high thrust requirements such as stamping, machining, or forming. However, they are better suited for high-speed assembly and transportation.

Ironless linear motors are sometimes referred to as "U-shaped" linear motors because their secondary part is shaped like a "U" and two magnetic plates are installed opposite each other. The main part (also known as the "thruster") is located in the U-slot between two magnetic plates.

The disadvantage of designing with an iron core is the cogging effect, which reduces the smoothness of motion. The occurrence of cogging effect is due to the slotted design of the primary component, which gives it a "preferred" position when moving along the magnet row of the secondary component. In order to overcome the trend of aligning primary and secondary magnets, the motor must generate greater force to counteract the trend, which can cause fluctuations in speed, known as cogging effect. The fluctuation of force and velocity can reduce the smoothness of motion, which may be a major issue in applications where high motion quality (not just final positioning accuracy) is required within the stroke.

Manufacturers use various methods to reduce cogging effects. A common method is to tilt the position of the magnets (teeth), which will be smoother when the primary passes through the secondary magnet. In addition, changing the shape of the magnet to a slender octagon can also achieve a similar effect.

Another method to reduce the cogging effect is called segmented winding. In this design, the primary coil has more laminated teeth than the magnets in the secondary, and the laminated stack has a special shape. These two designs together counteract the cogging force. In addition, this problem can be solved through software solutions. The algorithm for reducing cogging effects allows servo drivers and controllers to adjust the current provided to the primary coil, thereby minimizing changes in force and speed to the greatest extent possible.

Ironless linear motors do not have cogging effects because their primary coils are encapsulated in epoxy resin rather than wrapped around the iron core. The quality of ironless linear motors is relatively low (epoxy resin is lighter than iron cores, but has lower hardness), which enables the highest acceleration, deceleration, and operating speed to be achieved in electromechanical systems. The stability time of ironless motors is usually better (lower) than that of iron core motors. The primary coil does not use an iron core, and the disappearance of related cogging effects or speed pulsations also means that ironless linear motors can provide very low-speed and stable motion, with speed fluctuations typically less than 0.01% during low-speed operation.

How integrated is the linear motor?

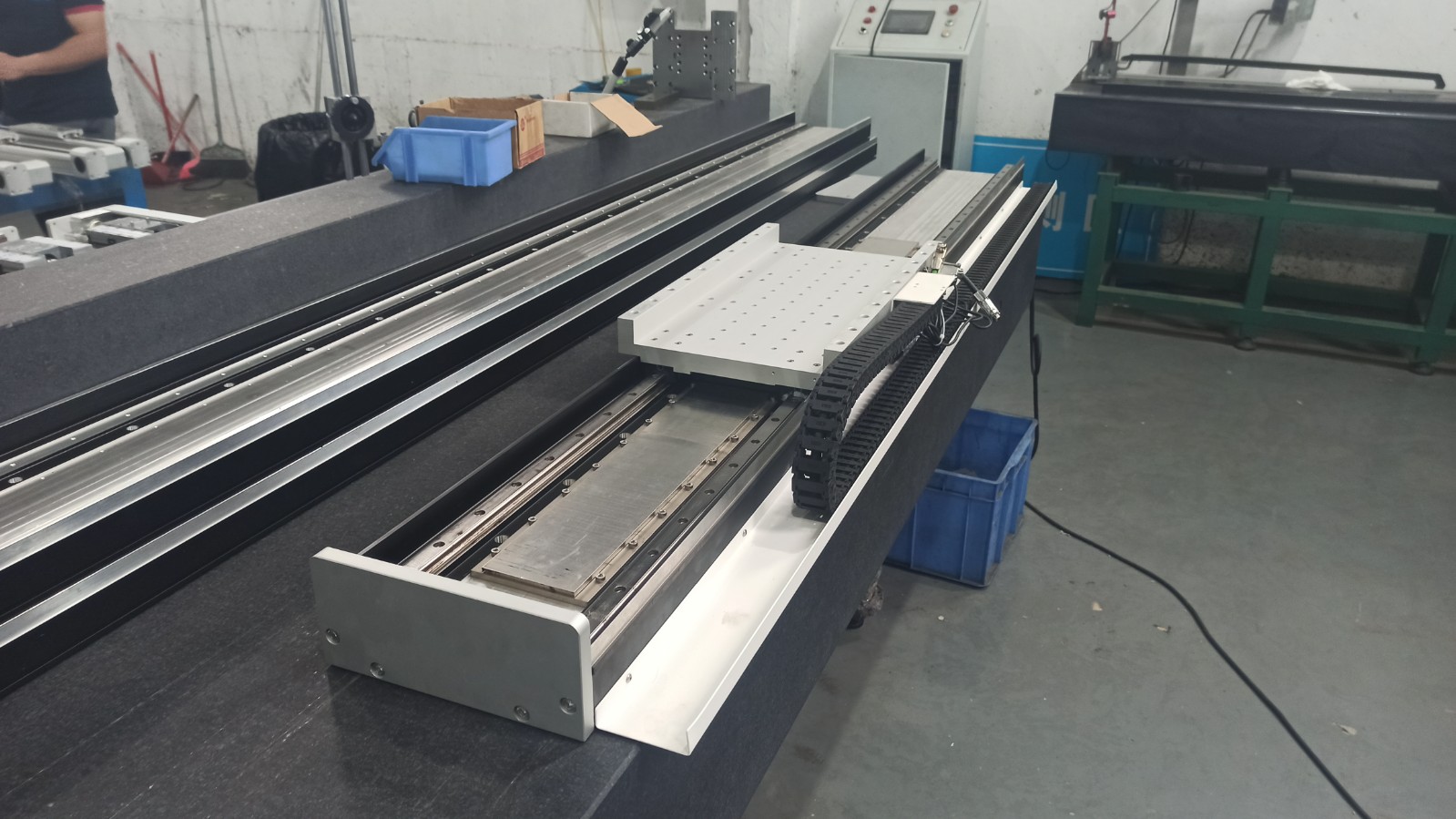

Like rotary motors, linear motors are just one component in the motion system. A complete linear motor system also requires bearings (guides) to support and guide loads, cable management, feedback (usually linear encoders), servo drives, and controllers. Experienced equipment manufacturers and machine manufacturers, or users with very unique design or performance requirements, can build complete systems using internal functionality and ready-made components from different manufacturers.

The design of linear motor systems can be said to be simpler, with fewer components and fewer labor-intensive assembly steps (without the need to align ball screw brackets or tension belts) compared to systems based on belts, gears, racks, or screws. Linear motors are non-contact, so designers do not have to worry about preparing for lubrication, adjustment, or other maintenance of the drive unit. But for original equipment manufacturers and machine manufacturers who are looking for turnkey solutions, there are countless options for complete linear motor-driven actuators, high-precision stages, and even Cartesian and gantry systems.

When selecting suitable linear guides for iron core linear motors, it is necessary to consider the attraction between primary and secondary components, which may increase the load on the linear guides. But ironless linear motors do not have this problem, because not using an iron core in the primary part means there is no attraction between the primary and secondary.

Is the working environment suitable for linear motors?

Linear motors are often the preferred solution in special environments such as cleanrooms and vacuum environments, as they have fewer moving parts and can be paired with almost any type of linear guide or cable management to meet the particle generation, degassing, and temperature requirements of applications. In extreme cases, the secondary (magnetic track) can be used as a moving component, while the primary component (winding, including cables and cable management) remains stationary.

However, if the environment is composed of metal debris, metal dust, or metal particles, linear motors may not be the best choice. This is especially true for linear motors with iron cores, as their design is essentially open, exposing the magnetic tracks to contamination. The semi enclosed design of ironless linear motors provides better protection, but attention should be paid to ensuring that the slots in the secondary components are not directly exposed to pollution sources. The design of enclosed linear motors with and without iron cores can solve the problem of pollution, but it may reduce the motor's heat dissipation capacity and potentially replace one problem with another.